Energy, whether it be traditional or clean, is a precious resource, drives economies, and meets a basic human need for thermal comfort while powering our lives.

The U.S. Energy Information Administration’s 2018 Commercial Buildings Energy Consumption Survey estimates that commercial buildings consume 39% of total energy in the United States[1].

There are two model energy efficiency standards for commercial buildings:

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE)

- ANSI/ASHRAE/IES Standard 90.1-2019 Energy Standard for Buildings Except Low-Rise Residential Buildings [2]

- International Code Council® (ICC®)

- International Energy Conservation Code® (IECC®) [3]

Both standards specify minimum requirements for energy efficiency and are updated in 3-year cycles; the most current versions are ASHRAE 90.1-2022 and IECC-2021.

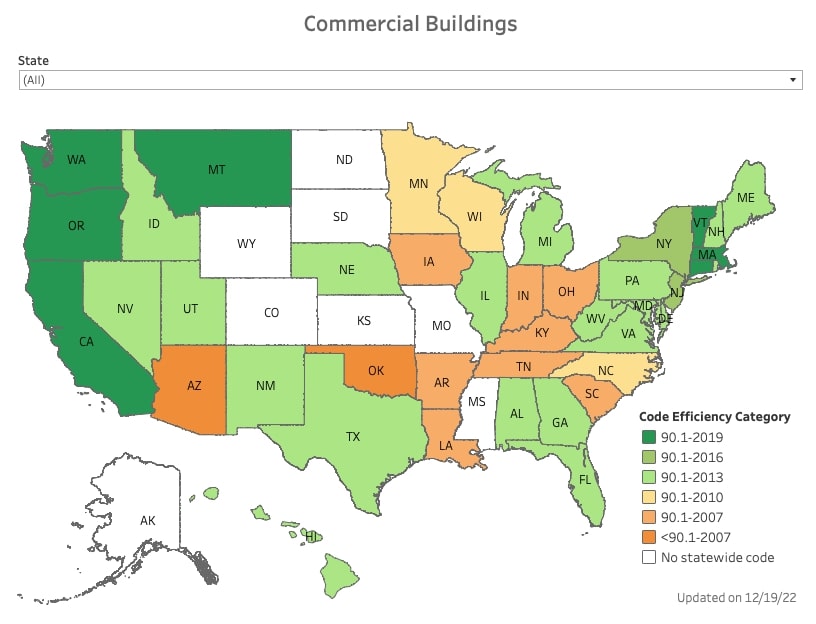

It’s important to understand that these standards must be adopted by states and/or local jurisdictions to become model building codes.

Commercial construction projects are often designed based on ASHRAE 90.1 as a compliance path for the U.S. Green Building Council’s (USGBC) Leadership in Energy and Environmental Design (LEED®) certification.

Most states adopt a version of the IECC and periodically update in an effort to improve energy efficiency. [4]

One particular building material plays a critical role in delivering energy efficiency. Although it’s not sexy, it’s proven to conserve energy. According to the National Insulation Association (NIA), mechanical insulation generates one of the most rapid returns on investment for building owners by saving energy. Based on a study conducted by the U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy, 82% of projects generated a return on investment (ROI) within 12 months of system start-up. [5]

Mechanical insulation insulates building mechanical systems such as HVAC, refrigeration, and plumbing. Components include piping, equipment, and ductwork. The design intent and performance benefits of mechanical insulation include:

- Saving energy

- Reduce greenhouse gas emissions

- Condensation control

- Process control

- Fire protection

- Noise control

- Personnel protection

There are many types of mechanical insulation, and no one type is appropriate for every application. Factors such as continuous operating temperature, environmental conditions, and design intent help determine the best insulation type.

Getting back to energy codes, both 90.1 and IECC specify minimum insulation thicknesses for the following applications:

- Pipe Insulation

- Duct Insulation

Minimum pipe insulation thickness (inches) is determined by these factors:

- Line (operating) temperature

- Nominal pipe or tube size

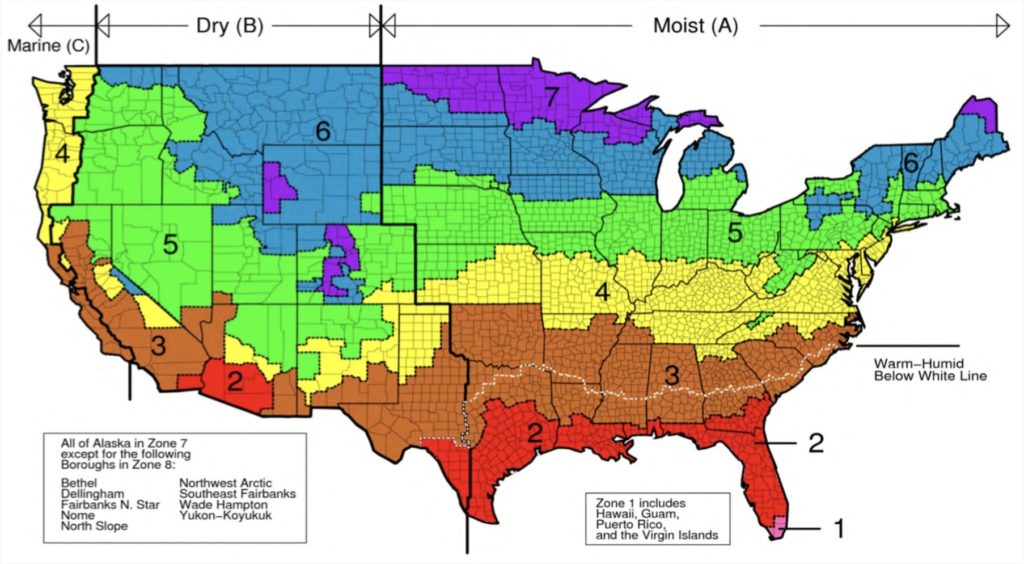

Minimum duct insulation thickness (R-value) is determined by these factors:

- ASHRAE Climate Zone [6]

- Building location (exterior, unconditioned space, indirectly conditioned space

- Supply or return

- Heating or cooling

ASHRAE Climate Zone (2018)

The R-value of duct insulation is calculated by dividing the thickness by thermal conductivity (k-value). For example, an R-value of R-8 for exterior and unconditioned spaces can be achieved with a 2” thickness and k-value of 0.245 {2.0/.245 = R-8.2].

ASHRAE 90.1 and IECC specify minimum insulation thicknesses for cooling systems such as chilled water, brine, and refrigeration. Operating temperature ranges are separated by 40ºF-60ºF and <40ºF. The primary concern when insulating these below-ambient “cold” systems is to control condensation.

ASHRAE specifies “closed-cell” insulation for cold applications. A proven closed-cell insulation solution for cold applications is closed-cell elastomeric foam (also known as rubber).

Due to its closed-cell structure, built-in vapor retarder (skin), flexible nature, and ease of installation, rubber is an excellent choice for long-term thermal insulation performance on refrigeration, chilled water, and domestic cold water systems.

Aeroflex USA’s AEROFLEX® EPDM™ closed-cell elastomeric insulation is inherently “nonpolar”, which means it is hydrophobic and does not attract or induce moisture. Below are additional performance benefits of AEROFLEX® EPDM™:

- Low thermal conductivity (reduced thicknesses)

- Low water vapor permeability (0.02 perm-inch)

- EPDM offers greater UV resistance than traditional NBR/PVC rubber

- Naturally microbial-resistant (no EPA-registered antimicrobial agent required)

- Non-corrosive on stainless steel

- Fire-safe (passes ASTM E84, UL723, CAN/ULC-S102 up to 2” thick)

- Low-VOC for chemical emissions

- Environmental Product Declaration (EPD)

- Health Product Declaration (HPD)

- Ultra-low PVC content

- Buy-American compliant

To learn more, click here.

Sources:

https://www.ashrae.org/ [2, 6]

https://www.energy.gov/eere/office-energy-efficiency-renewable-energy [4]