There are two model energy efficiency standards for commercial buildings:

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE)

- ANSI/ASHRAE/IES Standard 90.1 Energy Standard for Buildings Except Low-Rise Residential Buildings

- International Code Council® (ICC®)

- International Energy Conservation Code® (IECC®)

Both standards specify minimum requirements for energy efficiency and are updated in 3-year cycles. The most current

versions are ASHRAE 90.1-2022 and IECC-2024.

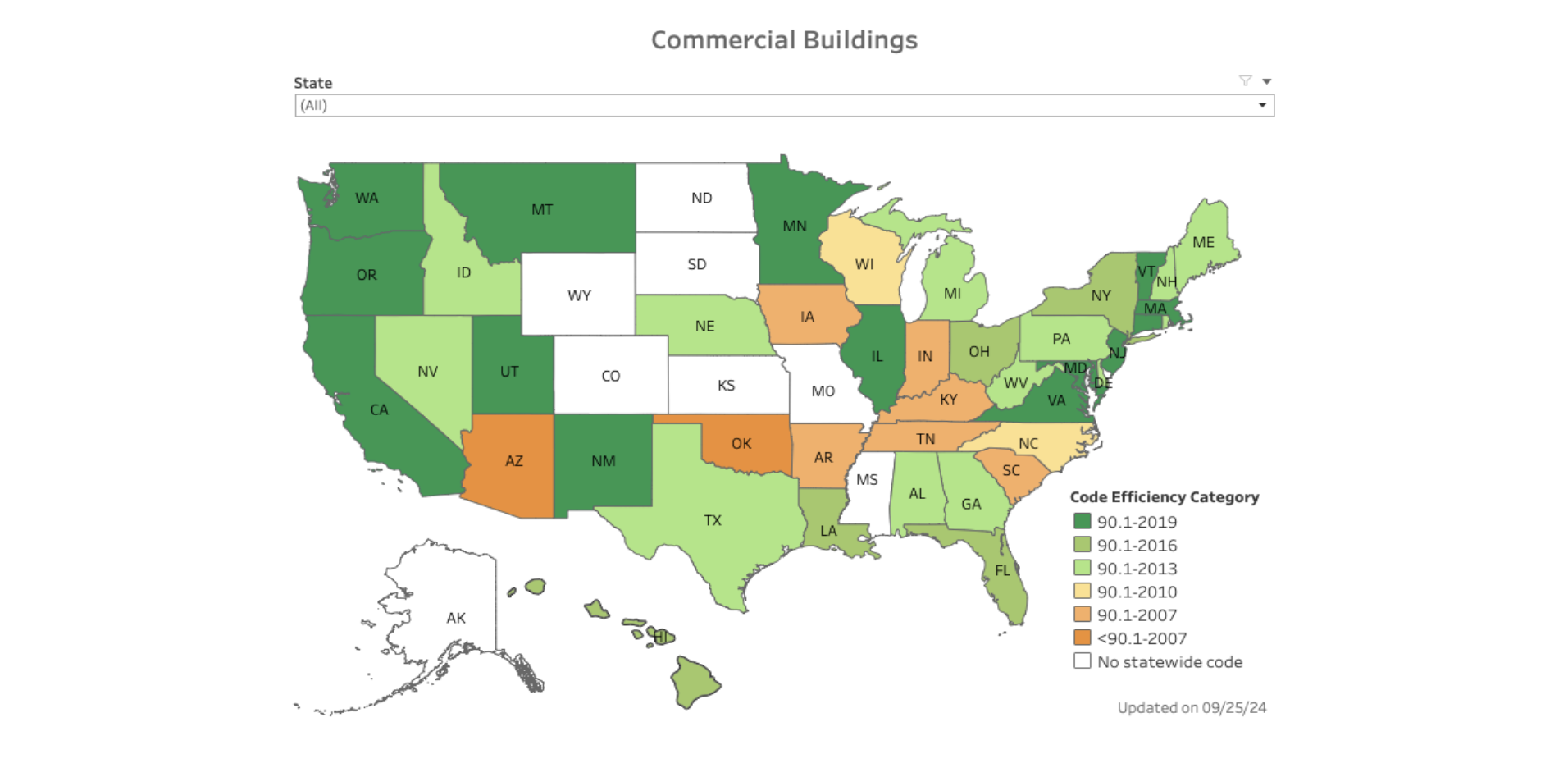

It’s important to understand that these standards must be adopted by states and/or local jurisdictions to become

model codes.

Commercial construction projects are often designed based on ASHRAE 90.1 as a compliance path for the U.S. Green

Building Council’s (USGBC) Leadership in Energy and Environmental Design (LEED®) certification.

However, most states adopt a version of the IECC and periodically update to improve energy efficiency. Below is the

status of state energy code adoption (September 2024).

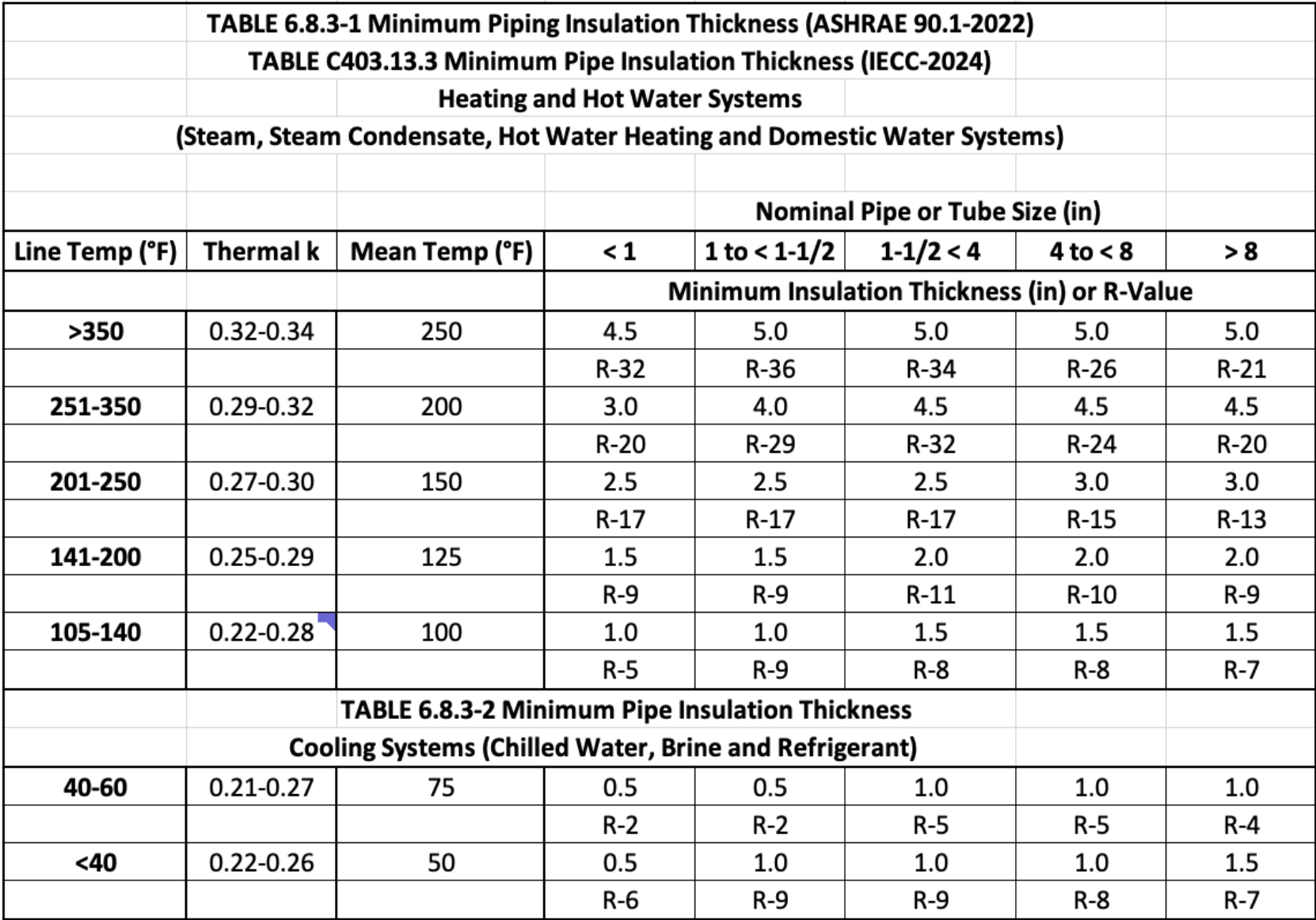

The Minimum Piping Insulation Thickness per ASHRAE 90.1-2022 and IECC-2024 are detailed below.

Note: Although the minimum piping insulation thicknesses remain unchanged, IECC added minimum R-Values to the 2024

code as “an option” to achieve energy conservation. Either minimum insulation thickness OR minimum R-value can be

selected. ASHRAE 90.1 will add R-values in the next update scheduled for 2025.

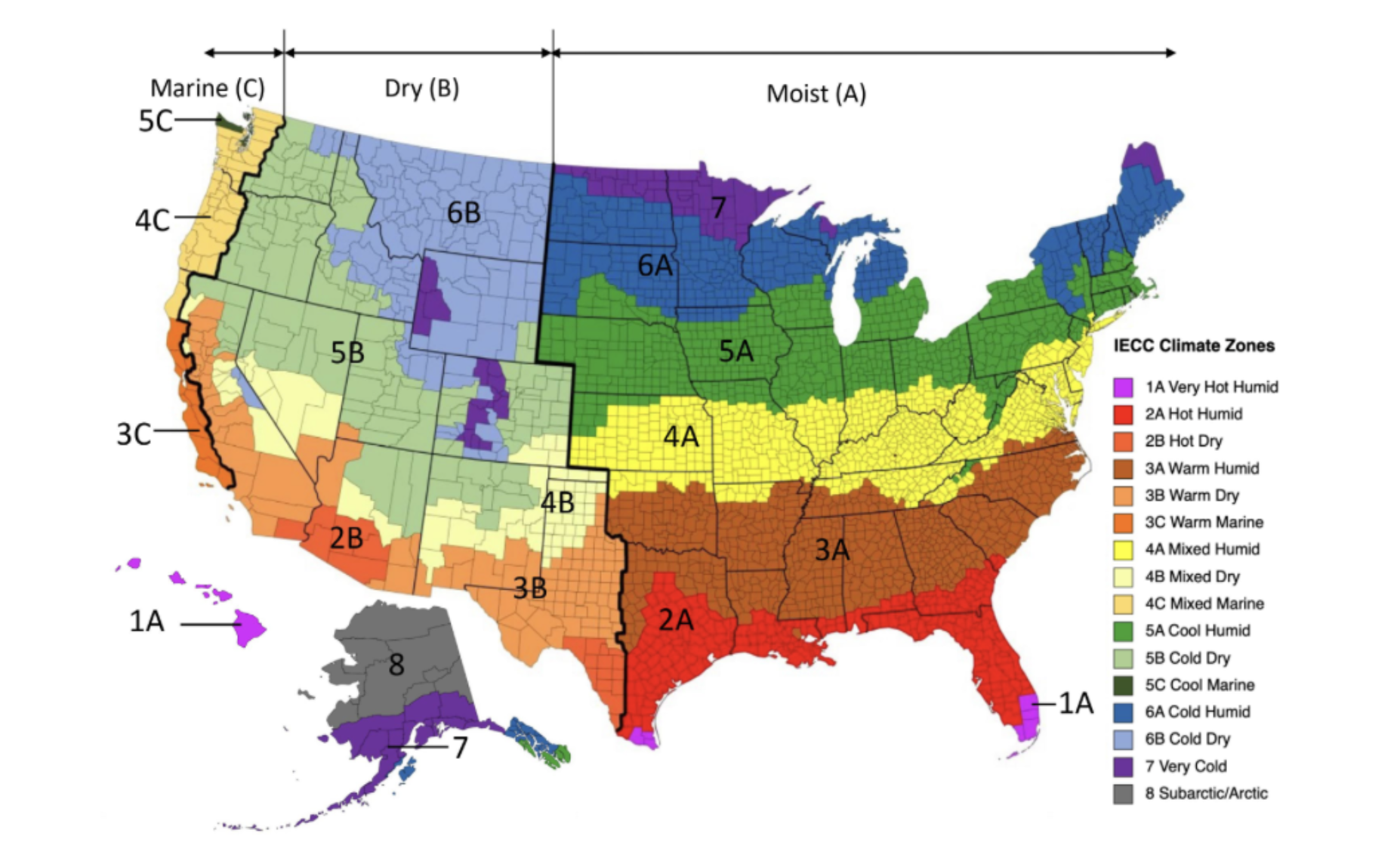

Minimum Duct Insulation Thickness is specified by R-Value depending on the climate zone of the project location in

the United States. Additionally, thickness is determined by the duct location on the project:

- Exterior (outside the building envelope)

- Unconditioned space (i.e. mechanical room)

- Indirectly conditioned space (i.e. spaces adjacent to conditioned spaces)

Below is the most current Climate Zone Map from IECC-2021.

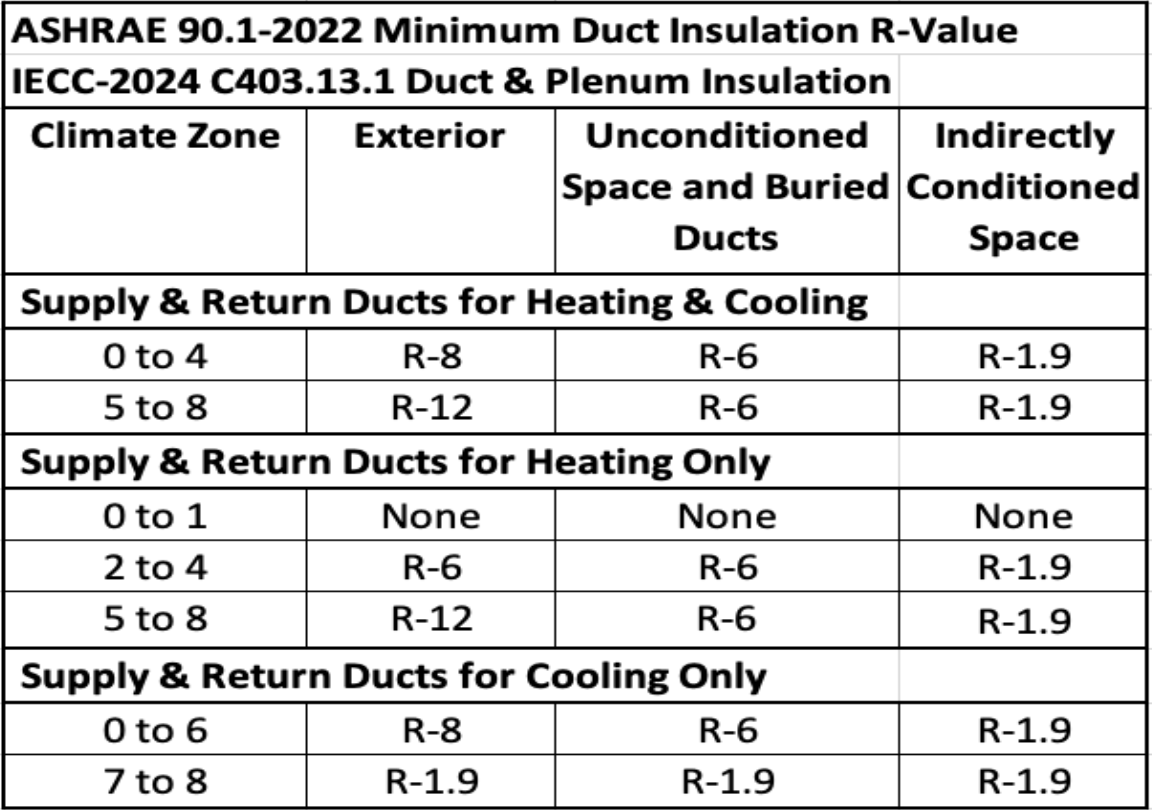

The Minimum Duct Insulation Thickness per ASHRAE 90.1-2022 and IECC-2024 are detailed below.

Energy codes do not specify insulation type –

The best pipe and duct insulation type for a given application should be selected based on characteristics such as:

- Composition (i.e. fibrous versus non-fibrous)

- Cell structure (i.e. closed cell versus open cell, rigid versus flexible)

- Operating temperature

- Thermal conductivity (k-value)

- Water vapor permeability (perm rating)

- Fire performance (25/50 flame & smoke developed indexes)

- Owner project requirements such as budget and sustainability (low-VOC, EPD, HPD)

Energy codes specify minimum insulation thickness or R-value for energy efficiency only –

- Insulating below-ambient piping & duct systems require special consideration such as condensation control and

mold prevention. - Chilled water and refrigerant piping are of particular concern. Closed-cell insulation with a vapor retarder

(built-in or supplemental) is proven to provide the best long term performance by effectively controlling

condensation. - Greater thicknesses may be required to control condensation due to specific project operating environments such

as low operating temperatures in high ambient and relative humidity conditions.

Important Takeaways

- Energy codes do not specify insulation type.

- Energy codes specify minimum insulation thickness or R-value for energy efficiency. Greater thickness may be

required for condensation control. - Either minimum insulation thickness OR minimum R-value meet the code. R-values have been added as an

“optional”

compliance path. Depending on the insulation type, the thickness may increase to meet minimum R-values.

To learn more about pipe insulation, click

here.

To learn more about duct insulation click here.