What do you need to look for in the best AC refrigerant line pipe insulation for your client’s project?

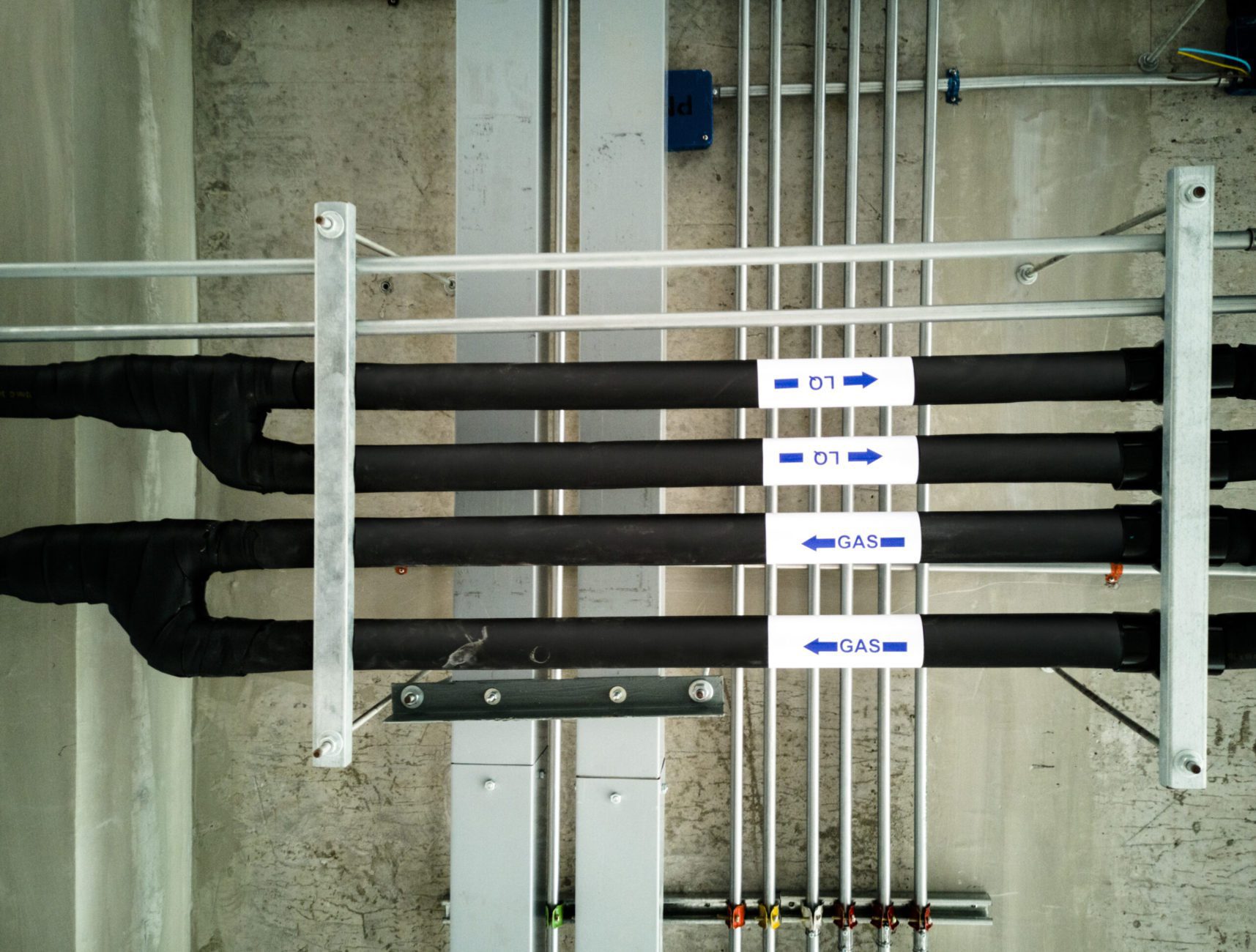

HVAC systems utilize piping to transfer cool/cold and warm/hot fluids to ultimately deliver conditioned air to a building’s occupant spaces. AC refrigerant line pipe insulation saves energy by preventing heat gain of the refrigerant while controlling condensation with the goal of protecting the AC’s metallic piping from a destructive phenomenon known as corrosion under insulation (CUI).

The cool/cold line is known as the suction line or ac return line. It conveys fluids, such as refrigerants, at temperatures of about 40°F [4.4°C]. The liquid line conveys warm/hot fluids at about 110°F [43.3°C]. Finally, the discharge line is typically very hot and operates at about 150°F [66°C].

There are numerous AC refrigerant line pipe insulation options to choose from, however one type in particular offers several advantages when compared to other types of AC refrigerant line pipe insulation; this will be explained later in this post.

AC refrigerant lines should always be insulated with AC refrigerant line pipe insulation when their operating temperatures are below the ambient temperature (cold) to prevent condensation on the insulation surface and resulting heat gain (energy loss) of the refrigerant.

Although liquid lines are warm/hot, they should be insulated with AC refrigerant line pipe insulation in spaces where the ambient temperature exceeds the liquid line temperature such as an unconditioned air plenum or attic. When personnel safety is a concern, AC refrigerant line pipe insulation should also be added for protection.

Discharge lines are not typically insulated, however, they should be insulated with AC refrigerant line pipe insulation when personnel protection is of concern and heat loss (energy loss) would not be desirable for the given application.

Closed-cell elastomeric foam pipe insulation, also known as rubber, is a proven AC refrigerant line pipe insulation type for ac refrigerant lines due to its closed cell structure and built-in vapor retarder. When the proper insulation thickness is selected, closed-cell elastomeric AC refrigerant line pipe insulation effectively controls condensation while preventing heat gain of the refrigerant.

Unlike some other AC refrigerant line pipe insulation types, closed-cell elastomeric insulation does not require a supplemental vapor barrier unless it will be subjected to extreme conditions (high ambient temperatures, high relative humidity, very cold operating temperatures, solar radiation) or mechanical impacts (foot traffic, extreme weather, birds). For ac refrigerant lines exposed to UV, such as roof-top applications, closed-cell elastomeric AC refrigerant line pipe insulation should be protected with the manufacturer’s specially-formulated protective coating or an insulation jacket to prevent solar radiation degradation in order to maximize the life cycle of the AC refrigerant line pipe insulation for the building owner.

Once installed, it’s important to periodically check the condition of the pipe insulation to ensure that it is undamaged and performing as intended. UV and mechanical damage to this particular pipe insulation can result in energy loss, due to a decrease in thermal efficiency and pipe corrosion, when the exposed AC refrigerant line is subjected to the elements.

Aeroflex USA’s Aeroflex® brand of EPDM (ethylene propylene diene monomer) closed cell elastomeric AC refrigerant line pipe insulation is available in preformed unslit, factory pre-slit (SSPT™) and continuous tubes to effectively insulate ac refrigerant lines. Aeroflex is designed to control condensation and heat loss for continuous operating temperatures of up to 257°F [125°C] and is safe for use on copper, aluminum, and stainless steel piping. Additionally, EPDM offers durable UV resistance when compared to traditional NBR/PVC rubber.

To learn more, visit https://aeroflexusa.com/epdm-pipe-insulation-benefits

Source: National Insulation Association https://insulation.org/io/articles/understanding-thermal-systems-industrial-refrigeration-systems/